Development and certification

Utva Aircraft Industry, a company certified by the Civil Aviation Directorate of the Republic of Serbia, deals with design and testing of aircraft components and assemblies, or the whole aircrafts, as well as with their certification according to EASA, FAR, and BCAR international standards. Also, thanks to the carefully selected teams of engineers engaged in several departments, this company produces the complete exploitation documentation – AMM, AFM, ICA, SRM, SME, IPC.

Product life cycle, phases – development, calculation, and manufacture

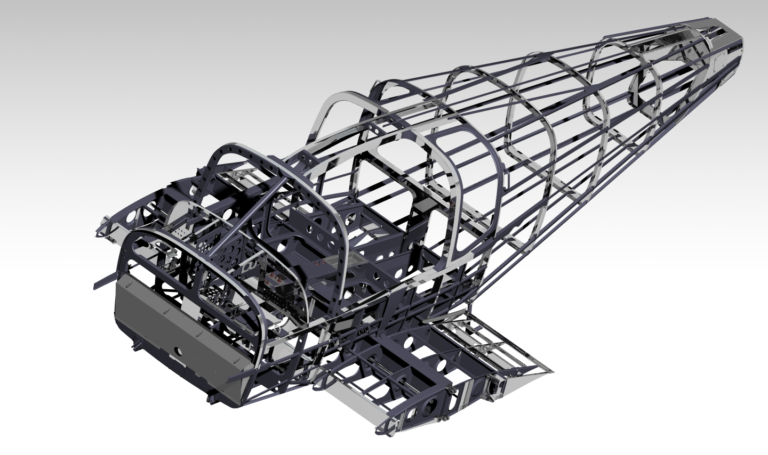

The design department produces the conceptual designs, primarily for the upgrades of specific components, assemblies or aircrafts, which requires detailed designs with overal 3D models (providing visualization of the designed item, thereby reducing the number of errors in the designing process), and technical documentation. It is also responsible for the follow-up of the overal proces, starting from the conceptual design of a component or assembly, to its installation in the aircraft, or the assembly of the whole aircraft.

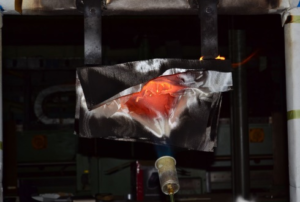

Firewall testing, and engine cowling testing

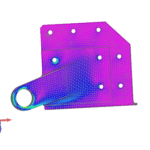

When calculating the hardness value, the test department analyzes the load as per the requirements of certification data bases, results of aerodynamic tests, data received during the test flights, and theorethical methods of load analysis. When testing the structure of individiual components, assemblies or entire aircrafts for hardness, we use a broad spectrum of knowledge and skills acquired in implementation of experimental, semi-empirical and theorethical methods of analysis to calculate the strain conditions, as well as the measurements/range of static and dynamic hardness tolerance.

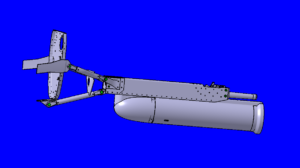

3D model of the antispin parachute; Utva 75 A41M aircraft static testing, and functional testing

The system department is engaged in design of the primary and secondary systems, such as the command, electrical, hydraulic, fuel, air conditioning, and pressurizing systems, which involves numerous detailed calculations, analyses, and experimental tests to optimize operation of every system.

Structural solution and visualisation of Utva 75 A41M airframe

The flight test department performs the full scope of development and certification testing within the design organization for the purpose of proving the product compliance with the project requirements and the certification base. We also perform static and dynamic tests, calibration, and performance tests. In addition, we perform so called „risky“ tests, i.e. those performed at the very limits of the flight envelope. They include spin tests, flutter tests, high speed tests etc. For that purpose, the department has developed its own test systems, such as the antispin parachute system, the system for vibrations generation during flutter testing, the probe tests for measuring the attack and slip angles etc.

Fuel system testing; spin testing; alpha and beta test probes of Utva 75 A41M aircrafts